HP-AHP65A Inverter/Charger for Superior Energy Efficiency

- 29 April 2024

- 2020 views

- No Comments

HP-AHP65A Inverter/Charger for Superior Energy Efficiency

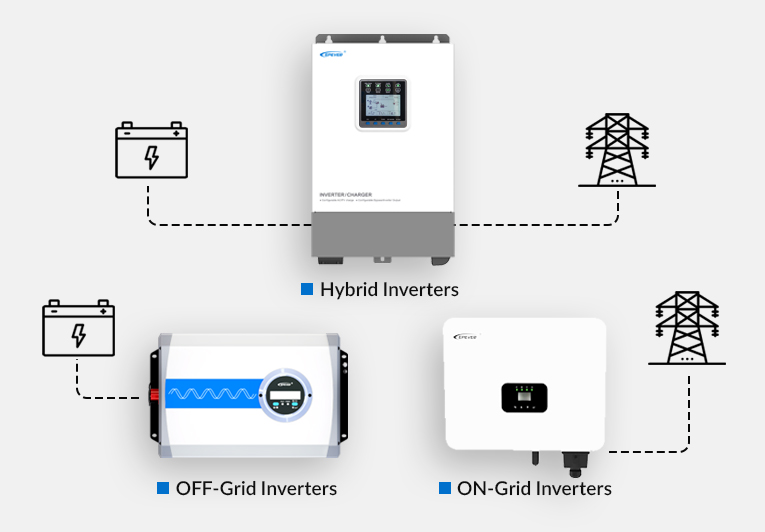

What is HP-AHP65A inverter/charger?

This hybrid inverter/charger, the HP-AHP65A, is meticulously engineered for superior energy capture and conversion efficiency. Crafted to withstand harsh conditions, it boasts IP65-rated protection, ensuring resilience against dust and water ingress. Versatile across a wide temperature range, the device operates reliably in extreme heat or cold, making it suitable for diverse environments, whether residential or commercial.

Equipped with the capability to manage inputs from two separate photovoltaic (PV) sources and compatibility with various generator types, HP-AHP65 offers unparalleled flexibility in energy management. Its automatic standby feature minimizes waste by seamlessly transitioning to standby mode when solar or grid power is unavailable.

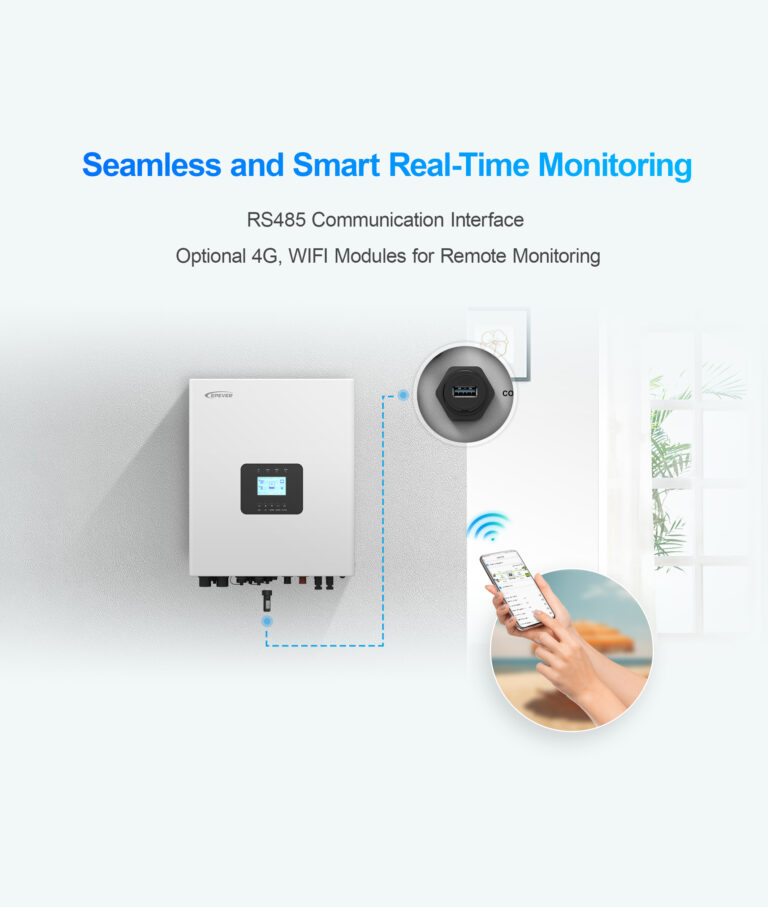

4G and WiFi modules, enable remote system adjustment and control, empowering users to manage their power needs conveniently from their smartphone or tablet.

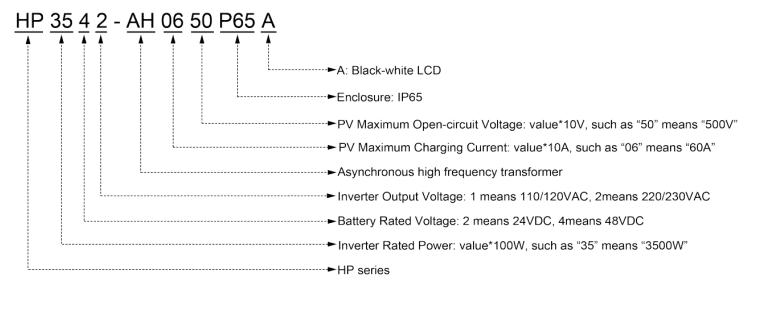

Product naming convention of HP-AHP65A

Our product model names are structured to give you quick insight into the features and specifications of each device.

Let’s break down the model HP3542-AH0650P65:

· HP Series: The prefix ‘HP’ indicates the series.

· 35: This number represents the inverter’s rated power in hundreds of watts. Here, “35” translates to a rated power of 3500 watts or 3.5 kilowatts.

· 4: Following the series indicator, the first single digit “4” denotes the nominal battery voltage. In this case, “4” signifies a 48V system.

· 2: The second single digit “2” reveals the inverter output voltage. “2” corresponds to an output of 220/230VAC, suitable for many household and commercial applications.

· AH: This section of the model name stands for the type of technology used, with “AH” indicating the use of an Asynchronous High-frequency transformer, which provides efficient energy conversion.

· 06: The next two digits “06” represent the maximum charging current times ten. Therefore, “06” indicates a maximum charging current of 60 amperes.

· 50: Similarly, the digits “50” indicate the maximum open-circuit voltage of the photovoltaic (PV) input times ten. Hence, “50” refers to a PV input voltage of up to 500 volts.

· P65: It represents the IP65 protection rating, which is placed after the “50” as a whole for better understanding.

· A: It represents the black-white LCD.

What are the HP-AHP65A highlights?

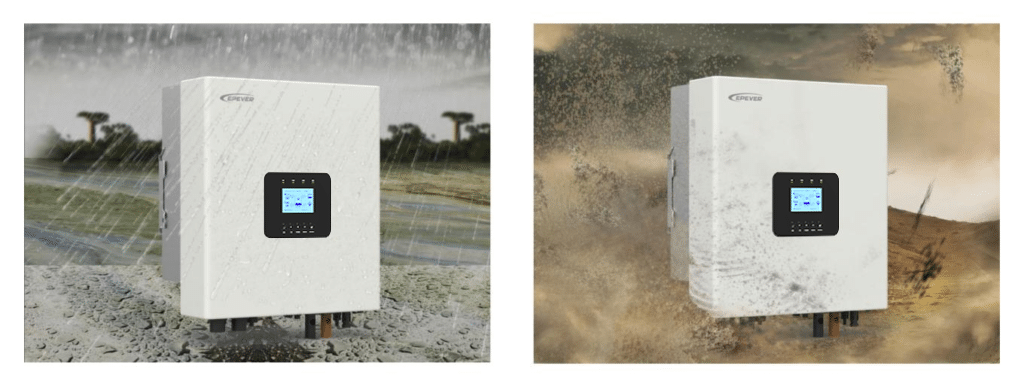

① IP65 high protection rating, suitable for harsh outdoor environments

The IP (Ingress Protection) rating system is an international standard used to define levels of sealing effectiveness of electrical enclosures against intrusion from foreign bodies (tools, dirt, etc.) and moisture. The rating system is defined by international standard IEC 60529.

The first digit indicates the level of protection that the enclosure provides against access to hazardous parts and the ingress of solid foreign objects. A rating of “6” means that the enclosure is dust-tight and complete protection against contact (a dust-tight product). The second digit indicates the level of protection that the enclosure provides against harmful ingress of water. A rating of “5” means that the enclosure can withstand water projected by a nozzle against the enclosure from any direction shall have no harmful effects.

IP65 rating on a product means that it is protected against dust ingress to the point where it will not interfere with the operation of the equipment; it is also protected against low-pressure jets of water from all directions

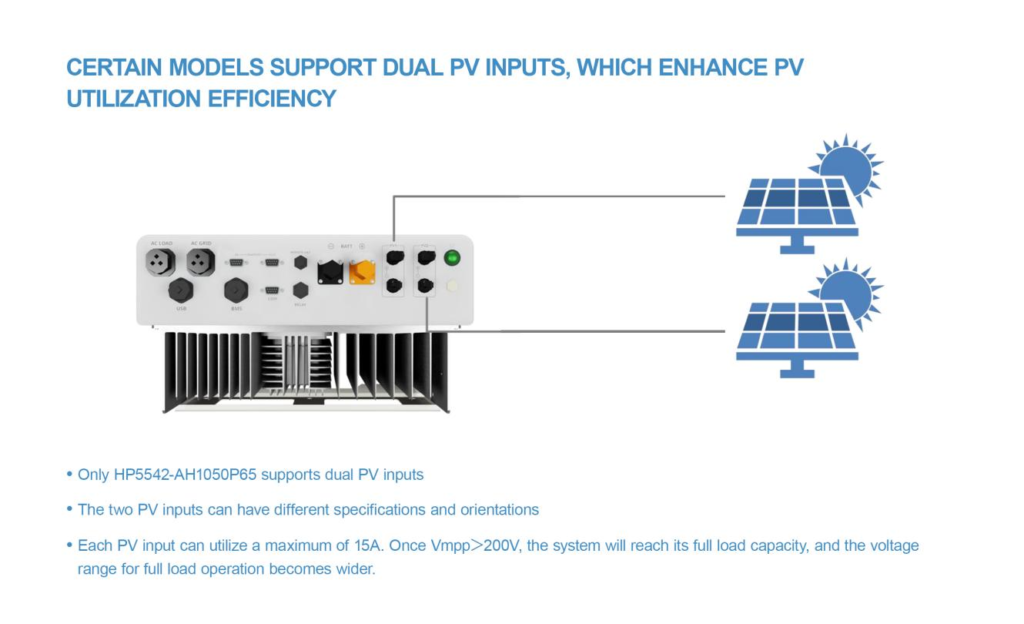

②Supports dual PV inputs (can be connected separately or in parallel), increasing PV utilization efficiency

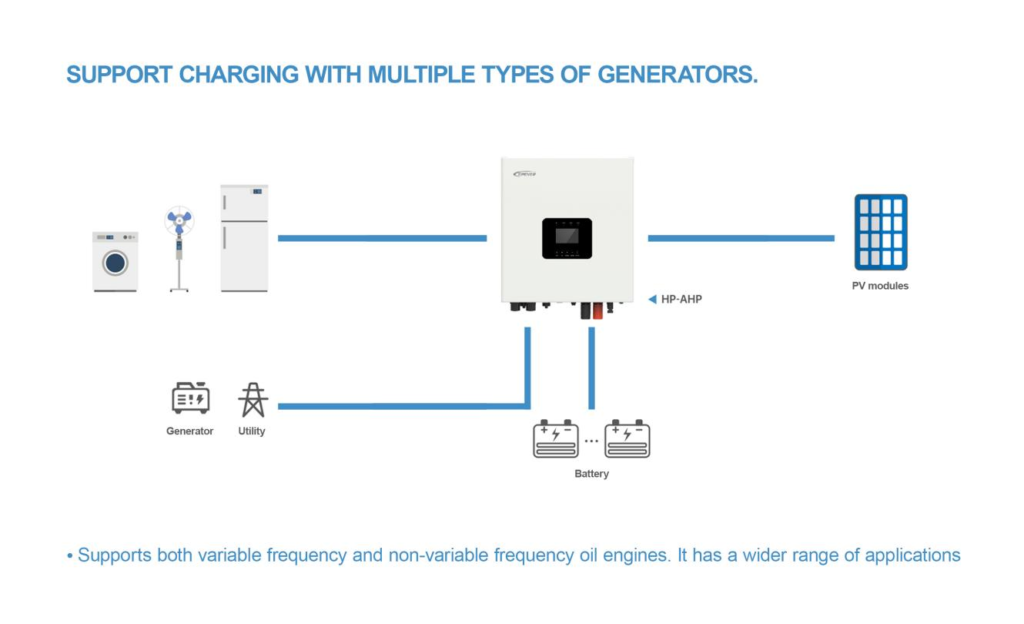

③The new HP-AHP65 is not limited to variable frequency. It is compatible with both non-variable frequency and variable-frequency generators, providing users with greater flexibility and choice

④Noise reduction design, noise level is below 45dB. It will provide you with a peaceful and quiet environment.

Without PV and grid connection, it can automatically enter standby mode after load shutdown. It can maintain low energy consumption, reduce energy waste, and improve device efficiency.

⑤The HP-AHP65 is equipped with an RS485 communication interface for reliable data transmission. For enhanced connectivity, optional 4G and WiFi modules are available, facilitating effortless remote monitoring and management.

Key product features of HP-AHP65A

The HP-AHP65 offers dual operating modes, allowing users to choose between battery-dependent or battery-independent operation. It incorporates a reliable lithium battery self-activation function, enhancing its adaptability to different usage scenarios. A dedicated communication interface ensures safe and controlled charging and discharging of lithium batteries.

Utilizing SPWM technology, the HP-AHP65 delivers pure sine wave output during DC to AC power conversion, catering to a wide range of AC loads, including household appliances, power tools, industrial machinery, and audiovisual systems.

With advanced MPPT tracking technology boasting a peak tracking efficiency of over 99.5%, the HP-AHP65 swiftly identifies and follows the maximum power point of PV arrays under various conditions, maximizing energy harvest from solar panels in real-time.

Charging is managed through a three-stage process — bulk, boost/equalize, and float charging — ensuring safe and efficient battery charging cycles.

An dot matrix LCD screen provides a clear and comprehensive display of system operations and status, enhancing user interaction.

Equipped with a standard Modbus protocol interface, the HP-AHP65 facilitates easy integration and flexibility in various monitoring setups.

Users have the flexibility to customize total charge and discharge current settings to accommodate different battery types, as well as specify maximum AC charging current to tailor AC charging capabilities according to their needs.

Product details

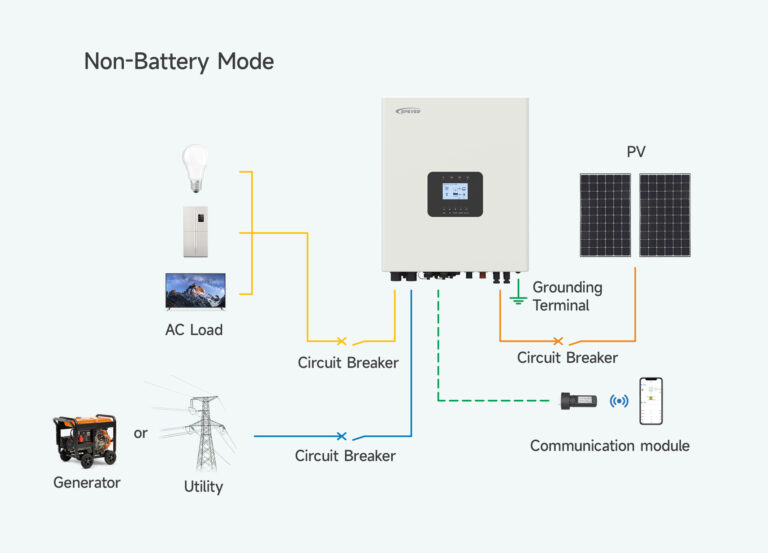

l Supports two operating modes:Battery mode & None-Battery mode

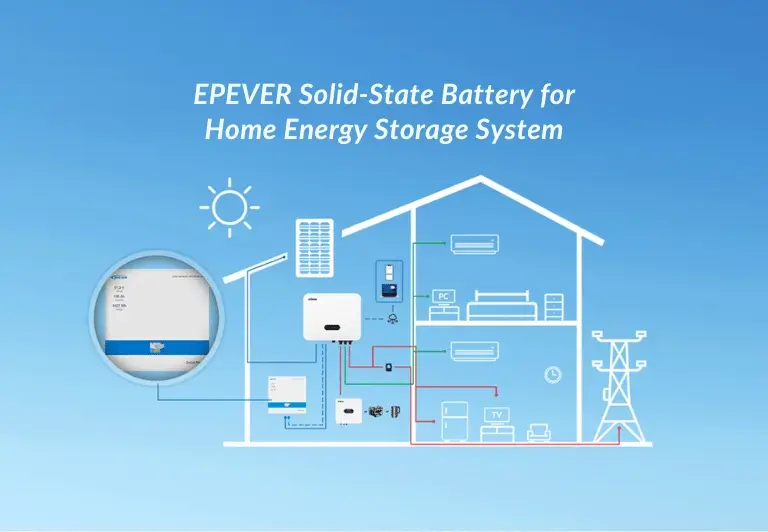

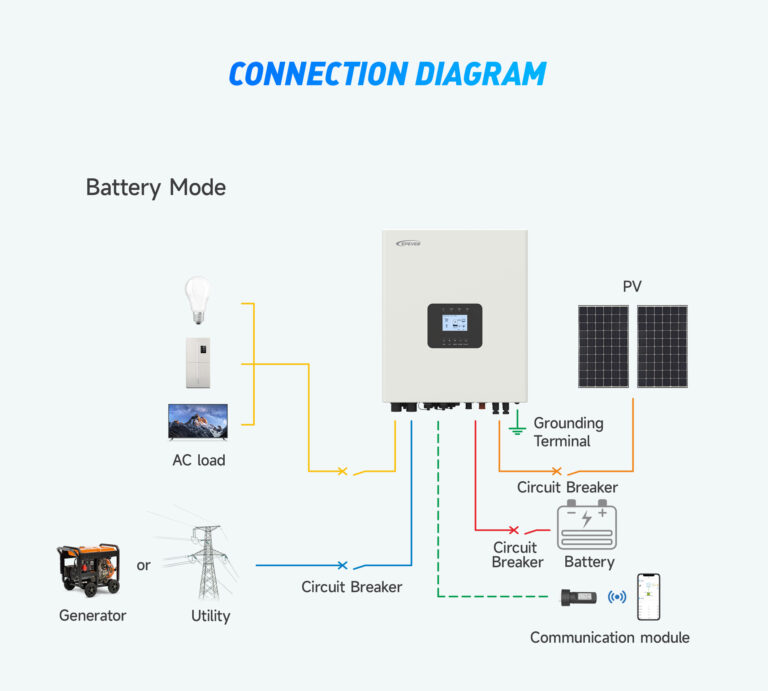

The HP-AHP65A system offers versatile power management solutions tailored to different energy generation and storage needs.

In the non-battery mode, the system directly connects to a PV array, utilizing an MPPT Charger to optimize solar power conversion. Even without batteries, it efficiently channels solar energy to household appliances and AC loads, ensuring an uninterrupted power supply.

Alternatively, during low sunlight or at night, the system seamlessly switches to draw power from the utility grid or an external generator. This ensures continuous power flow to connected loads, enhancing reliability.

For users requiring energy storage, the second operating mode incorporates a battery configuration. The HP-AHP65 inverter/charger intelligently manages energy, charging batteries during surplus power from the PV array or utility grid, and discharging stored energy when needed.

Both setups offer interactive monitoring through the LCD panel, allowing users to easily track system performance and status. These connection options demonstrate the adaptability and robustness of the HP-AHP65 system, providing users with a reliable power management solution for diverse scenarios.

l 4 Charging Modes

PV charge only: In this mode, the battery is charged solely from the solar panels without relying on an external power source. It is suitable for areas without access to the grid and where solar energy is abundant.

PV (solar) Priority: This mode prioritizes solar power, allowing the system to maximize the utilization of solar energy and reduce dependence on the grid. This helps lower energy costs, especially in areas with ample sunlight, significantly reducing electricity expenses.

PV+ Utility Charge: This mode provides a more stable power supply. Solar panels take precedence in supplying power, and when solar energy is insufficient or during nighttime, the system switches to grid power. This ensures a continuous and stable power supply even when solar panels are unable to operate or sunlight is limited.

Utility Priority: In this mode, the system primarily relies on grid power and only switches to alternative energy sources when grid power is unavailable or unstable. This mode is suitable for scenarios that rely on grid power and prioritize power supply stability.

l Battery Types

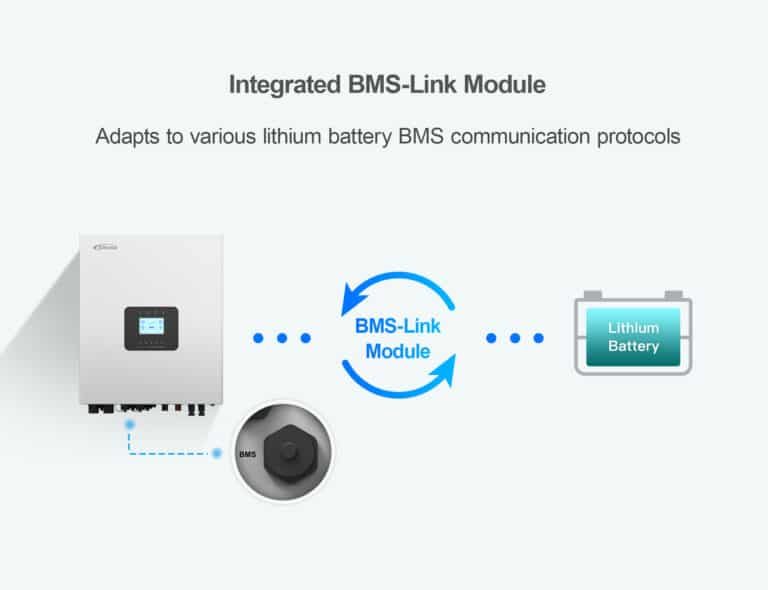

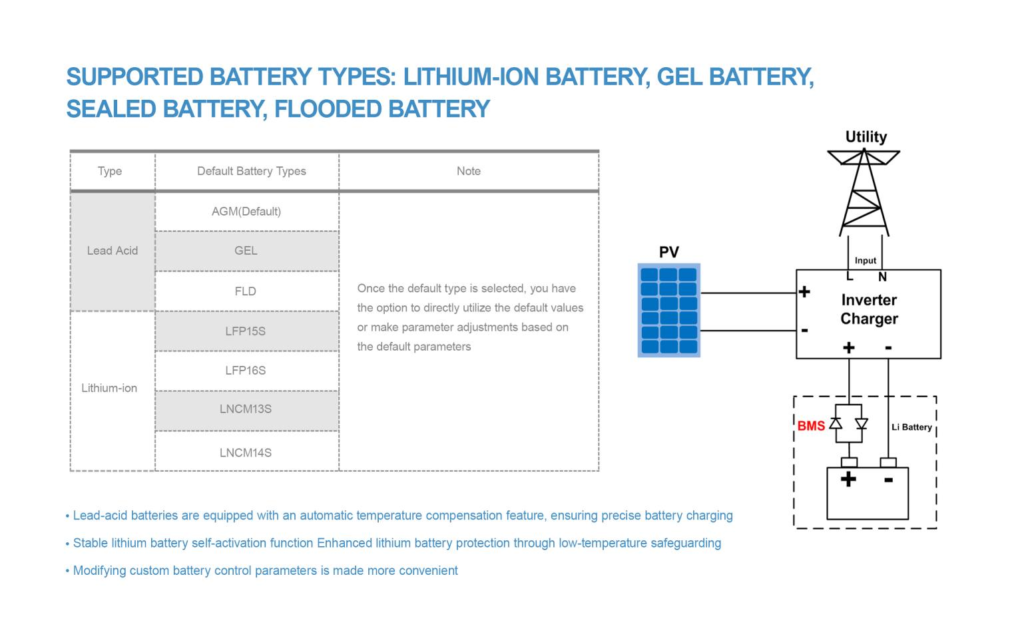

The HP-AHP65A inverter integrates the BMS-link module. It adapts to various lithium battery BMS communication protocols and it is engineered to provide flexibility in energy storage and management by accommodating various battery types. This compatibility empowers users to select the most suitable battery type based on their specific energy requirements, operational conditions, and budget constraints. The supported battery types include:

Lithium-Ion Batteries: Renowned for their high energy density and extended lifespan, lithium-ion batteries offer lightweight and efficient energy storage solutions. The HP-AHP65A features a dedicated communication interface for lithium batteries, ensuring precise control over charge and discharge operations to enhance safety.

Lead Acid Batteries: This category encompasses AGM (Absorbent Glass Mat), GEL, and FLD (Flooded) batteries, prized for their reliability and cost-effectiveness. AGM batteries, being maintenance-free and versatile, are the default choice due to their optimal performance under various conditions. The lead-acid batteries benefit from automatic temperature compensation, adjusting the charging voltage based on temperature fluctuations to achieve optimal charging.

Sealed and Flooded Batteries: Sealed batteries offer hassle-free maintenance, while flooded batteries may provide a longer service life and cost savings. The HP-AHP65 supports both types, allowing for flexible system design and maintenance approaches.

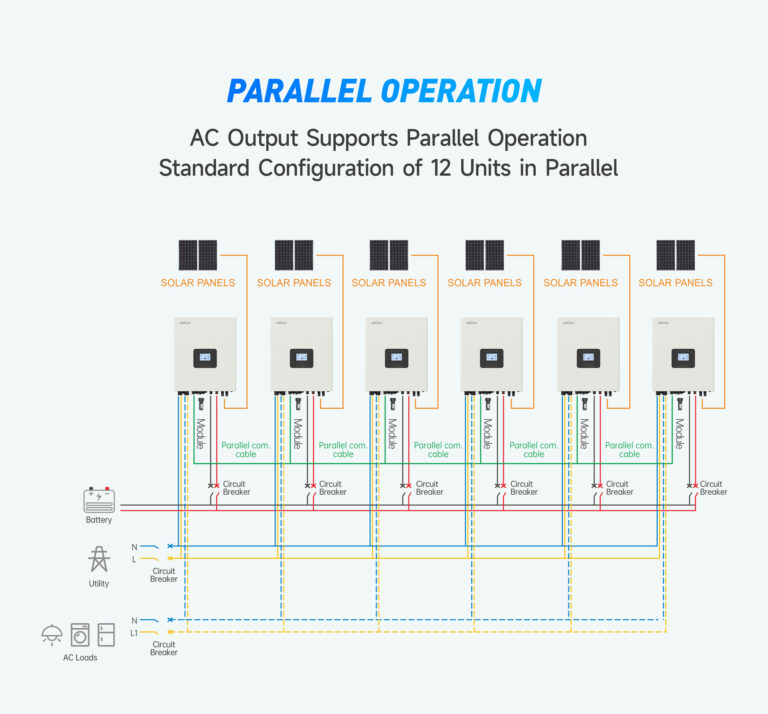

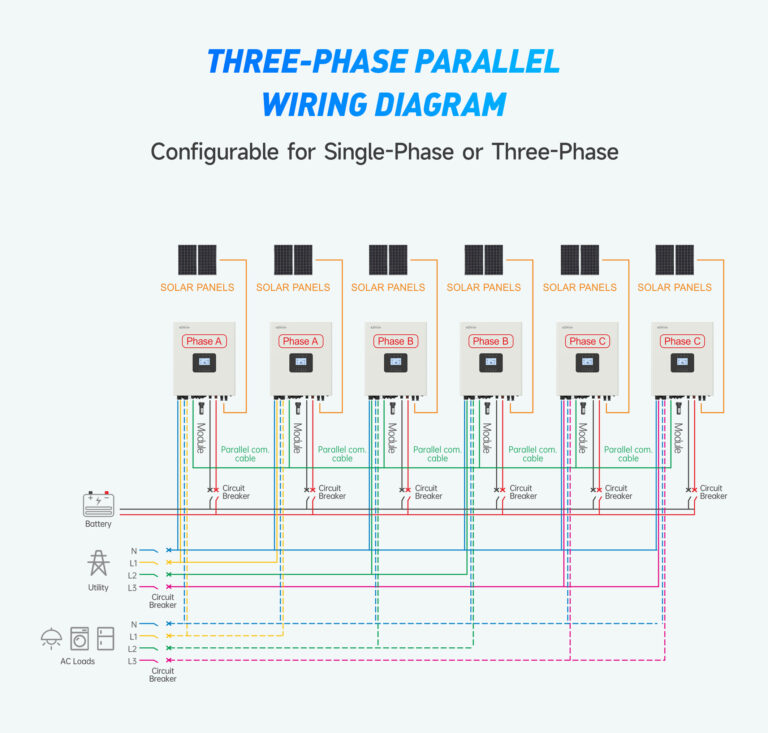

l Parallel connection

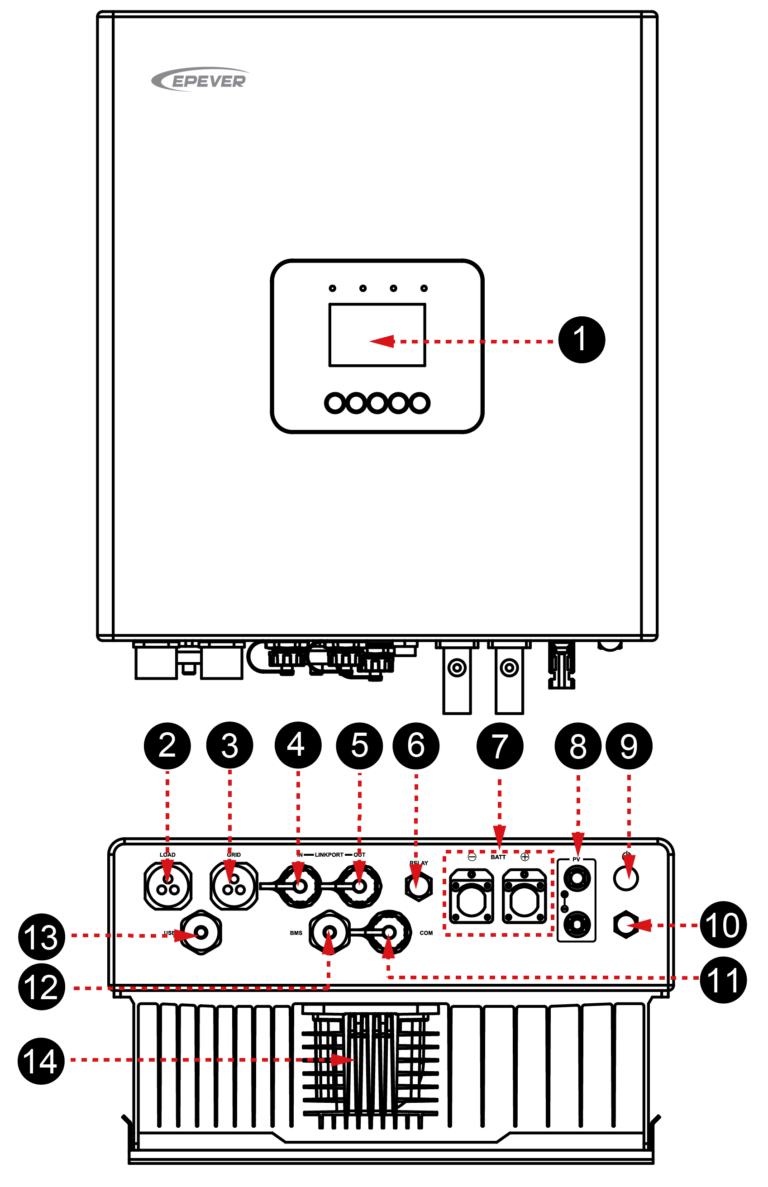

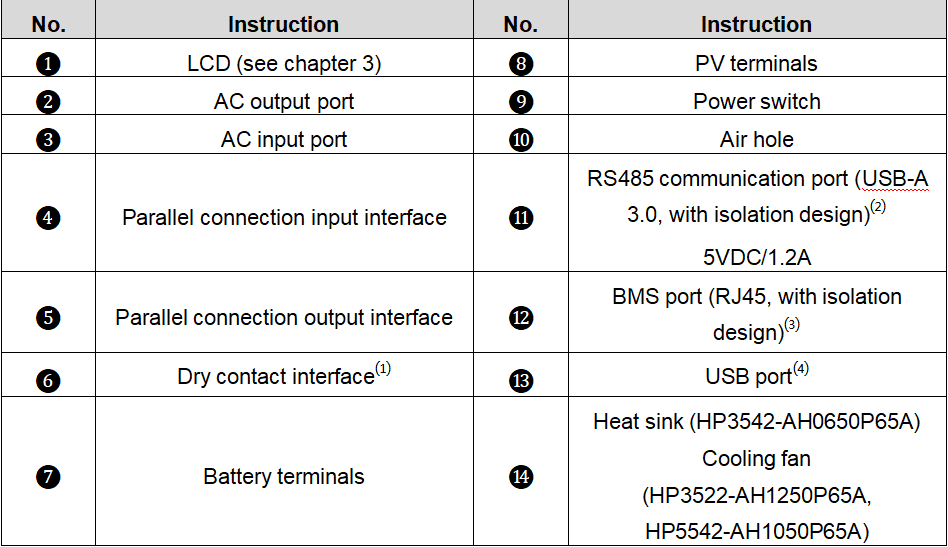

Appearance and Wiring:

The HP3542-AH0650P65A stands out as an advanced and dependable inverter/charger, meticulously designed to meet diverse power needs. Packed with a variety of connectors and controls, it guarantees both user-friendliness and efficiency. Every aspect of the unit is carefully engineered to simplify system management and operation, ensuring seamless functionality across different environments. Below is a concise overview of the key components of the HP3542-AH0650P65, working together to offer a robust and user-centric energy solution.

① LCD: The user-friendly screen allows users to easily adjust and monitor system parameters.

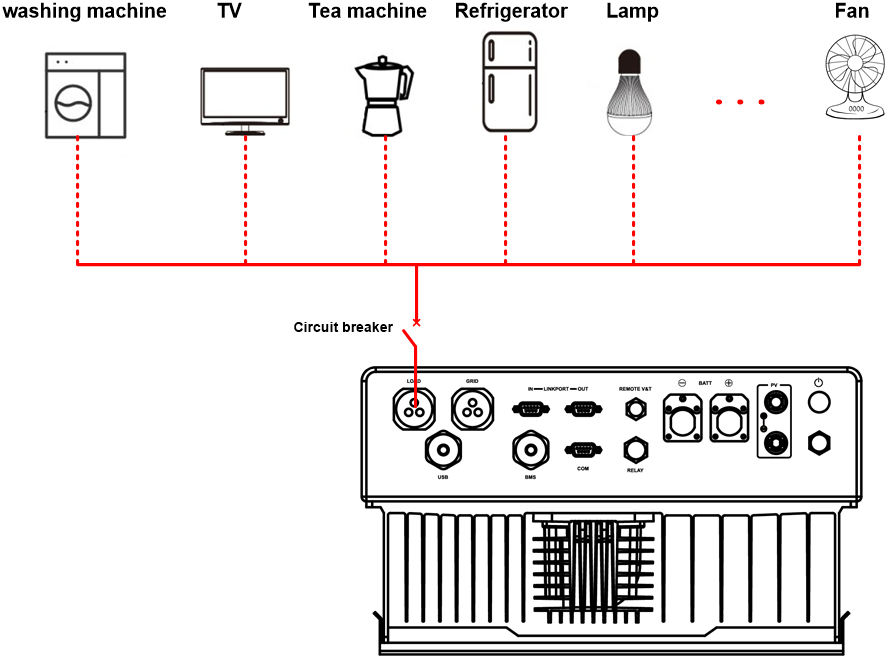

② AC output port: It delivers the converted AC power from the inverter/charger to various electrical devices and appliances.

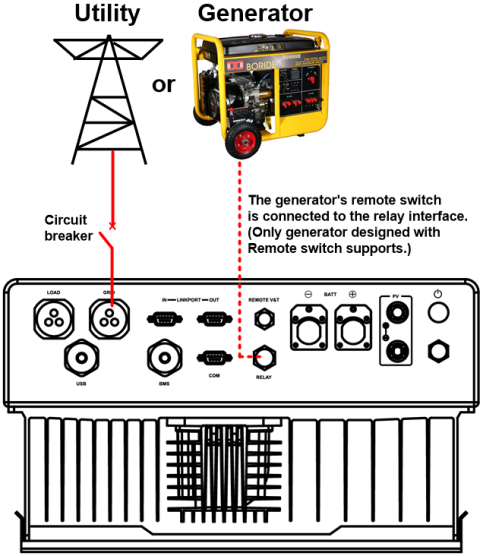

③ AC input port: This interface links the inverter charger with utility power or a generator, permitting AC power input from these sources and guaranteeing a consistent power supply.

④ Multiple-connection input/output interface (Reserved): This inverter offers the potential for multiple connections, paving the way for future expansion. This design feature signifies the system’s flexibility in adapting to various applications and connectivity needs while reserving room for the introduction of new functionalities.

⑤ Multiple-connection output interface (Reserved): This is reserved for future use, and offers enhanced versatility to accommodate various connectivity needs.

⑥ Remote battery voltage and temperature sampling port: This allows you to monitor battery statutes in real-time. You can access crucial information about the battery bank, aiding in optimizing system performance and maintaining battery health.

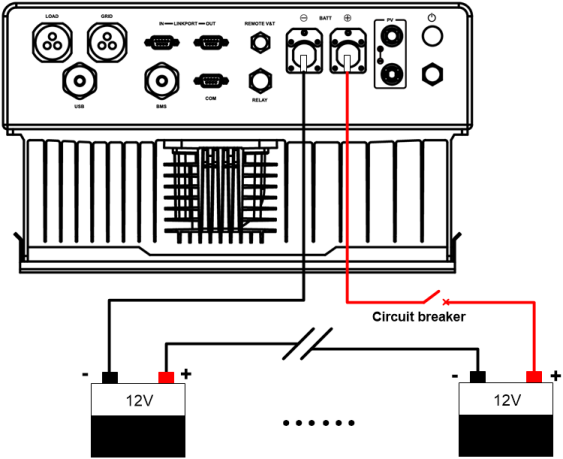

⑦ Battery terminals: The battery terminals provide reliable connection points for linking the battery bank. Engineered for secure and stable battery connections, these terminals ensure the required energy storage for the system, offering continuous energy support during peak demand or power outages.

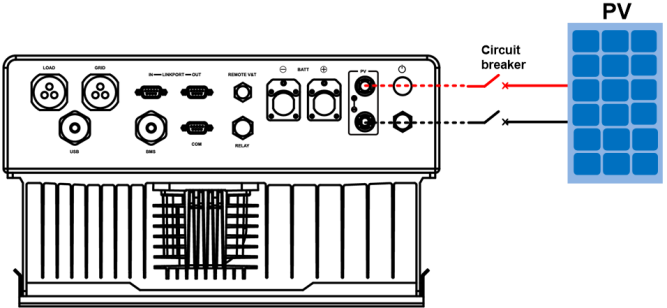

⑧ PV terminals: The PV terminals serve as connection points for solar panels, streamlining the incorporation of photovoltaic energy into the system. This design facilitates the efficient capture and utilization of solar energy, enhancing the system’s energy harvesting capabilities.

⑨ Power switch: The device features an integrated power switch, granting convenient control over the system’s power supply. Beyond providing user-friendly operation, this switch allows for swift power disconnection during maintenance or emergencies, ensuring the secure operation of both the system and devices.

⑩ USB port: Update the inverter/charger’s software after connecting the inverter/charger to a computer by a standard USB com. cable

⑪ BMS-Link port: Through a BMS-Link module, different lithium battery manufacturers’ BMS protocols can be converted into our company’s standard BMS protocol. In addition, it realizes the communication between the inverter/charger and the BMS

⑫ RS485 interface: Connecting with the RS485 interface, an optional 4G or WiFi module can remotely control the inverter/charger.

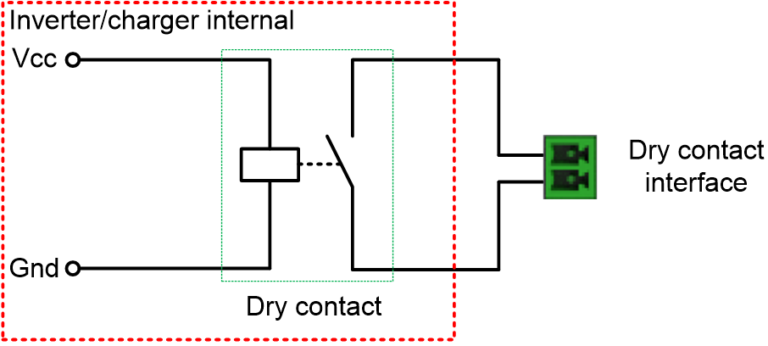

⑬ Dry contact interface: The dry contact interface is connected with the generator switch to turn on/off the generator. It can be used in parallel with the oil engine switch.

Operating principle: When the battery voltage equals the “dry contact open voltage,” the relay coil is energized, and the contacts close. The dry contact can drive a resistive load of 125VAC/1A, 30VDC/1A.

⑭ Cooling fan/Heat sink: The cooling fan and heat sink are components designed to manage and dissipate heat generated during the system’s operation.

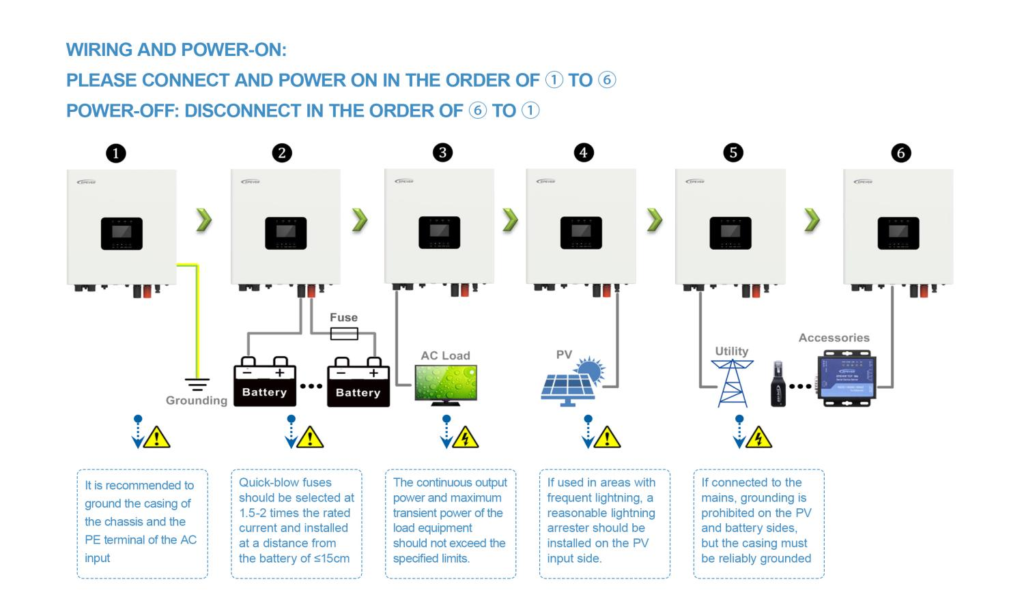

Wiring

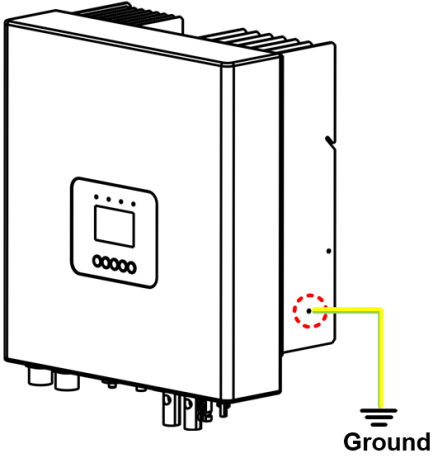

1.Grounding

The inverter/charger has a dedicated grounding terminal, which must be grounded reliably. The grounding wire size must be consistent with the recommended load wire size. The grounding connection point shall be as close as possible to the inverter/charger, and the total grounding wire shall be as short as possible.

2. Connect the battery

3. Connect the AC load

4.Connect the PV modules

5. Connect the utility or generator

Accessories

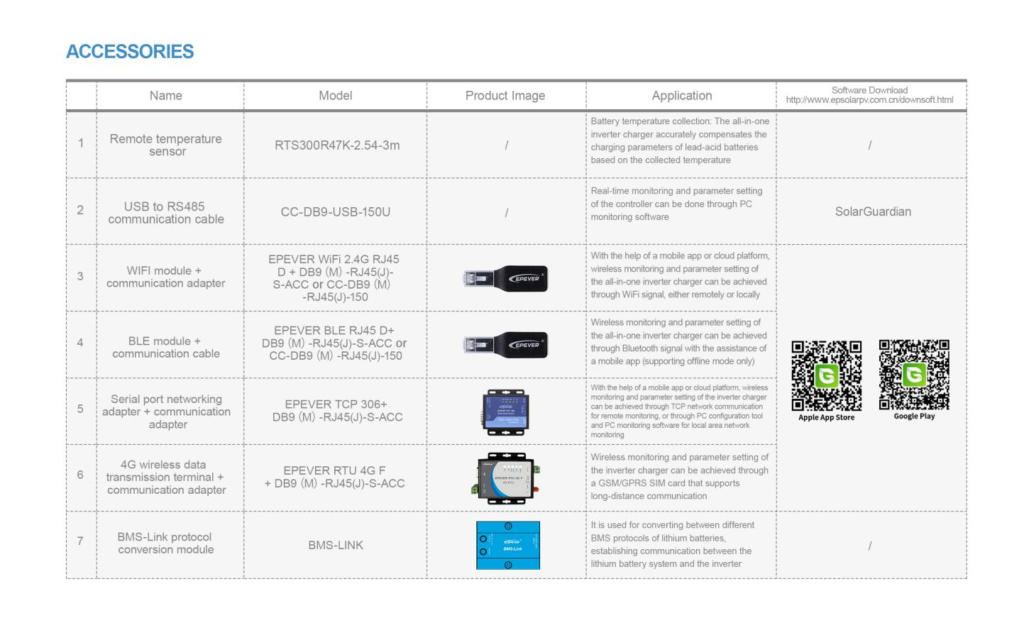

The HP-AHP65 series is accompanied by an array of accessories meticulously crafted to augment functionality and offer comprehensive energy management solutions.

Below is a detailed overview of the available accessories:

The HP-AHP65A isn’t simply an inverter charger, it symbolizes a pathway to a future defined by versatility, sustainability, and reliability. Whether you’re nestled in a remote community, in need of steadfast power backup, or yearning for energy independence, this device surpasses expectations. Delve deeper on the EPEVER official website and YouTube channel.