Why Choose Solid-State LFP Batteries?

- 27 September 2024

- 1385 views

- No Comments

Why Choose Solid-State LFP Batteries?

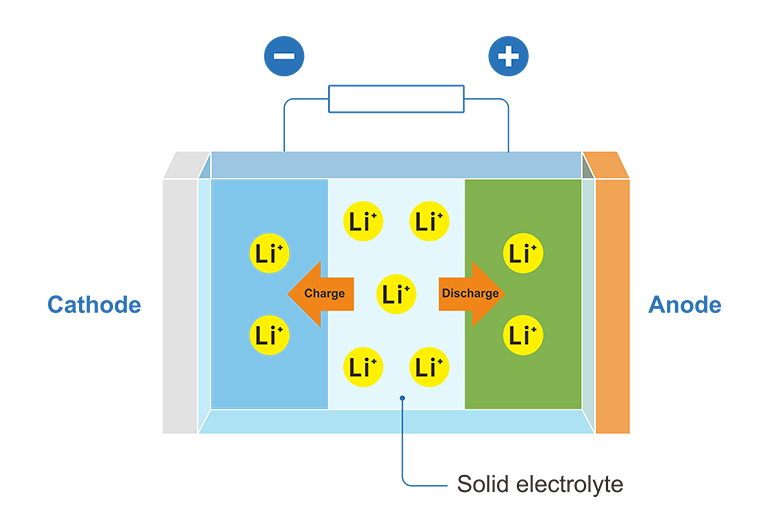

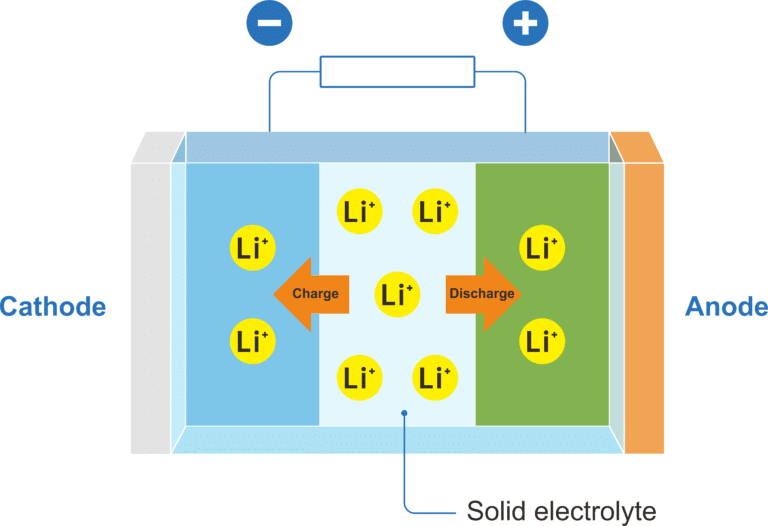

What is a Solid-State LFP Battery?

Solid-state LFP(Lithium Iron Phosphate) batteries are a battery technology that uses a solid electrolyte, effectively shifting the site of lithium-ion migration to a solid electrolyte medium. It differs significantly from conventional lithium batteries. The biggest distinction between Lithium and LFP batteries lies in their structure and usability.

Lithium batteries are constructed with a single cell and are designed for one-time use only, meaning they must be disposed of after their charge is depleted. Conversely, LFP batteries are built to be rechargeable, allowing for repeated use. They can be recharged and depleted multiple times, often enduring hundreds of charge cycles.

What are the advantages of Solid-State LFP Batteries?

• High Safety: The solid electrolyte is non-flammable, significantly reducing the risk of thermal runaway and effectively suppressing the growth of lithium dendrites, thus preventing short circuits;

• High Energy Density: Solid electrolytes are compatible with high-capacity anode and cathode materials, significantly enhancing the battery’s energy density—up to double that of current ternary lithium batteries;

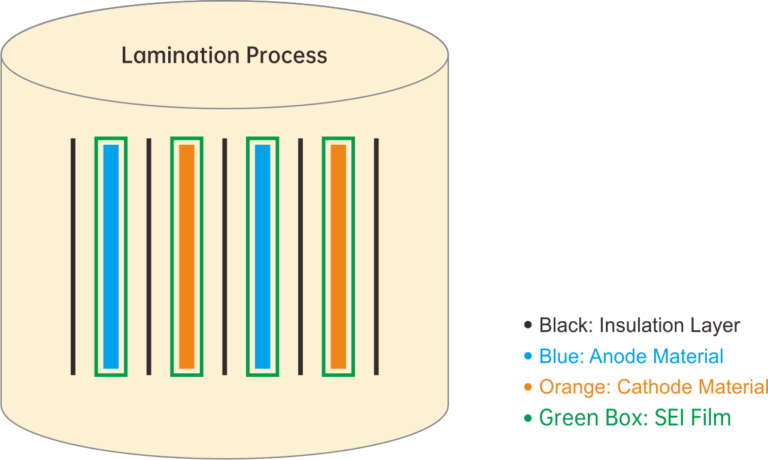

• Long Cycle Life: Solid electrolytes address the issue of SEI (Solid Electrolyte Interface) film formation during charge-discharge cycles, suppressing lithium dendrite formation, thus improving battery cycle performance and lifespan.

What is the SEI film of LFP battery?

SEI (Solid Electrolyte Interface) film, is a passivation layer formed on the surface of electrode materials during the first charge-discharge cycle of a lithium-ion battery, resulting from the reaction between the electrode materials and electrolyte at the solid-liquid interface.

What are the effects of SEI films?

• Reducing charge-discharge efficiency: SEI film formation consumes some lithium ions, increasing the battery’s irreversible capacity and reducing the charge-discharge efficiency of electrode materials.

• Improving cycle performance and lifespan: The SEI film is stable in organic electrolytes, insoluble in organic solvents, and effectively blocks solvent molecules, preventing co-intercalation of ions, thus protecting the electrode materials and enhancing cycle performance and lifespan.

Due to the self-discharging characteristics of lithium batteries, a typical lithium battery pack experiences a self-discharge rate of 3%-5% per month. Consequently, if lithium batteries are stored for an extended period, they may become overly discharged, causing the BMS(Battery Management System) to stop functioning. This prevents the battery pack from being able to charge. For this reason, lithium batteries need to be regularly and periodically charged or undergo charge-discharge cycles.

• Precautions for Recharging Lithium Batteries: The output voltage of the charging equipment should be equal to the number of battery cells in series multiplied by 3.2V (for lithium iron phosphate batteries); The maximum output current of the charging equipment should be less than 0.5C.

• How to Avoid the Need for Recharging: Increase the State of Charge (SOC) before shipping, as previously shipped lithium batteries typically had an actual SOC of 9%-10%; the new shipping standard is 35%-40%. Ensure stored lithium batteries are charged in a timely manner or recharged before shipment. Remind distributors/customers that if storage time exceeds three months, the batteries must be charged at least once for no less than 30 minutes @ 0.5C.

LFP batteries operate best between 15°C and 35°C, and performance is impacted outside this range.

• Increased electrolyte viscosity: Low temperatures increase electrolyte viscosity, affecting ion conduction and reducing charge-discharge performance

• Increased internal resistance: Cold weather reduces the efficiency of chemical reactions inside the battery, increasing internal resistance and further reducing battery performance

• Reduced material activity: In both lithium iron phosphate and ternary lithium-ion batteries, low temperatures reduce the activity of the anode and cathode materials, leading to longer charging times, difficulty in fully charging the battery, and faster power depletion.

Common Heating Methods for Lithium Batteries

• External heating: Using an external heat source such as heat fluids, phase-change materials, or heating elements to heat the battery pack via convection or conduction;

• Internal heating: Utilizing heat generated by internal resistance within the battery. This method has high energy efficiency, good temperature uniformity, and lowers the complexity and cost of the heating system. Internal heating methods include three-electrode self-heating, DC heating, AC heating, and pulse heating.

Why can't it heat during discharge?

Since the battery’s minimum discharge temperature can go as low as -20°C, discharging at low temperatures does not significantly affect battery life unless done frequently; Heating during discharge adds a small resistance in parallel with the external load, which may sometimes interfere with the load’s normal operation; Additionally, if an inductive load is connected during discharge and is suddenly powered down, the inductive load could damage the performance of the PI heating film or break down the heating circuit MOS.

Conclusion

The effective operation and longevity of solid-state LFP batteries hinge on proper thermal management and regular maintenance routines. Users should ensure that these batteries are charged according to the recommended practices, especially maintaining the SOC within the optimal range to prevent over-discharge. Batteries should be kept within an ideal temperature range of 15°C to 35°C, mitigating the risk of performance degradation in cold conditions.

By adhering to these guidelines, the risks can be minimized, thereby enhancing the overall efficiency and lifespan of the batteries. Regular checks and balances, along with adherence to the detailed operational recommendations, will ensure that solid-state LFP batteries operate at their highest efficiency, supporting their use in a wide array of applications without frequent need for recharge under varied environmental conditions.